Machinery & Plant Engineering

Your specialists for long-term solutions

Our team is made up of engineers and technicians who specialize in developing, designing and building customized solutions in mechanical, apparatus and plant engineering.

Our projects are well represented in the automotive industry, mechanical engineering and surface technology. Whether robotics, automation, electroplating, strip systems, painting lines, wastewater systems, electroplating drum & rack systems, we know our way around and have specialists for every necessary branch.

Electroplating systems with innovation and technology (green thinking)

Turnkey systems, composed of successfully established modules, applicable to all common and special surface technology finishing processes.

Electroplating baths, Reel-to-Reel line, wastewater and exhaust air systems, waste heat utilization. On this page you will find detailed information about the process.

From planning to series commissioning, we are your permanent contact for plant engineering specializing in surface finishing.

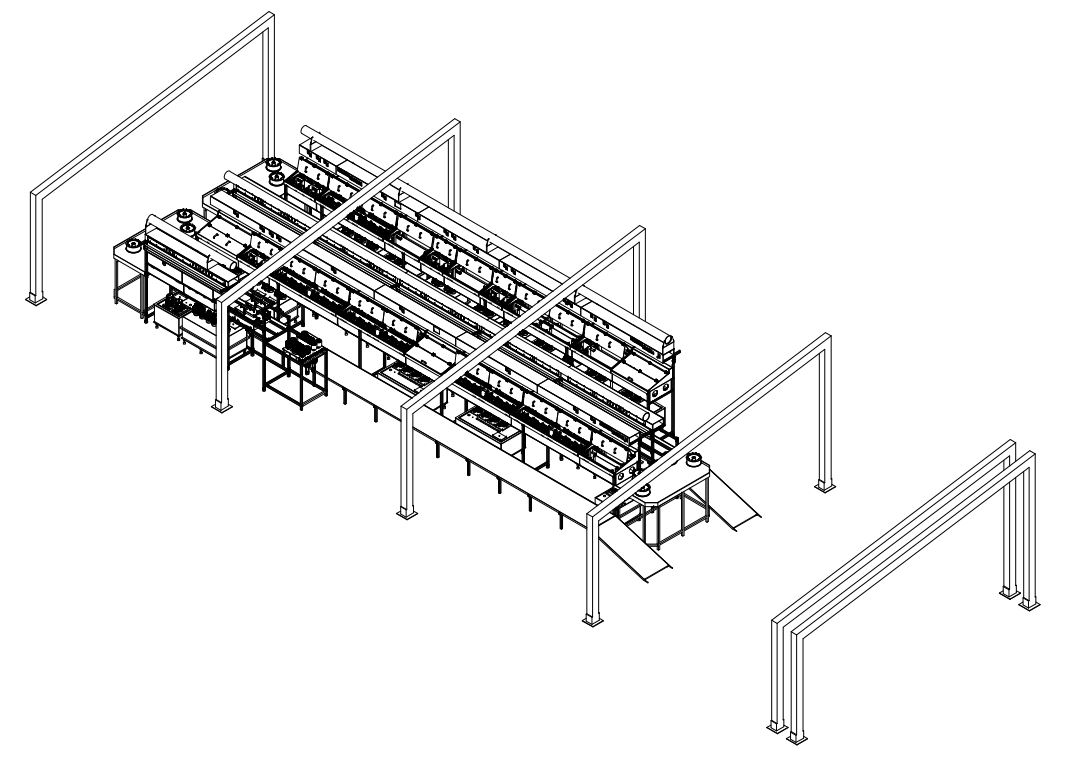

Reel-to-Reel line according to your needs

Our specialists will support you in creating belt systems that are individually tailored to your needs.

The properties of the material and the spatial conditions are determined in order to design an optimal solution for your concerns. Our systems can be designed for small and large rooms.

We are familiar with all types of electroplating systems, as well as unwinding and rewinding, straightening, feeding, oiling, post-treatment and part connection.

We coordinate all modules perfectly for you.

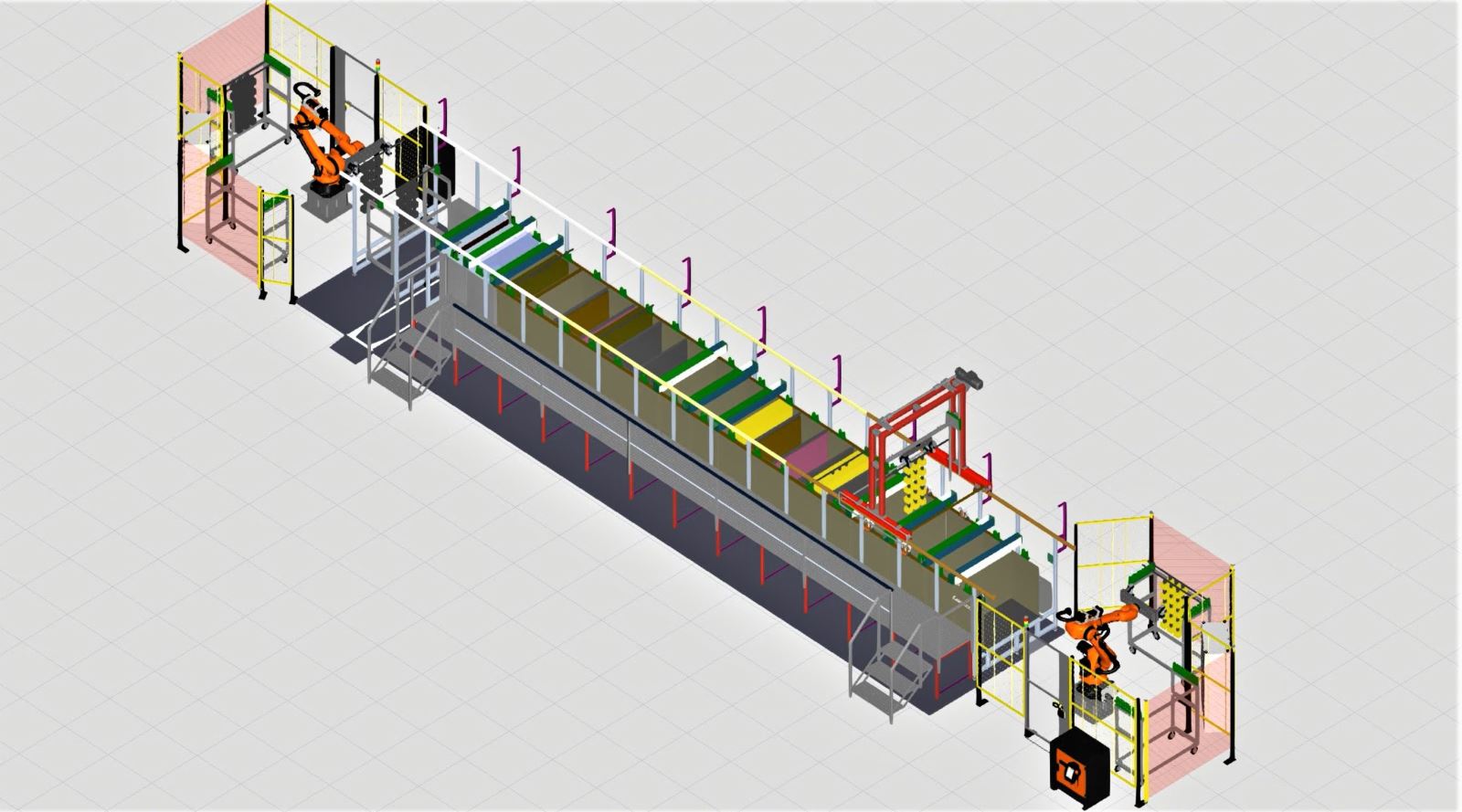

Rack Plating Machine

Rack machines know no limits when it comes to size and weight. This opens up a variety of possibilities depending on the influencing factors of the process to be used and the economic factors.

The variety of applications is reflected in your special solutions.

Popular surface refinements at OTSM GmbH include copper (Cu), nickel (Ni), tin (Sn), silver (Ag), zinc (Zn), chromating (Cr VI free) and phosphating.

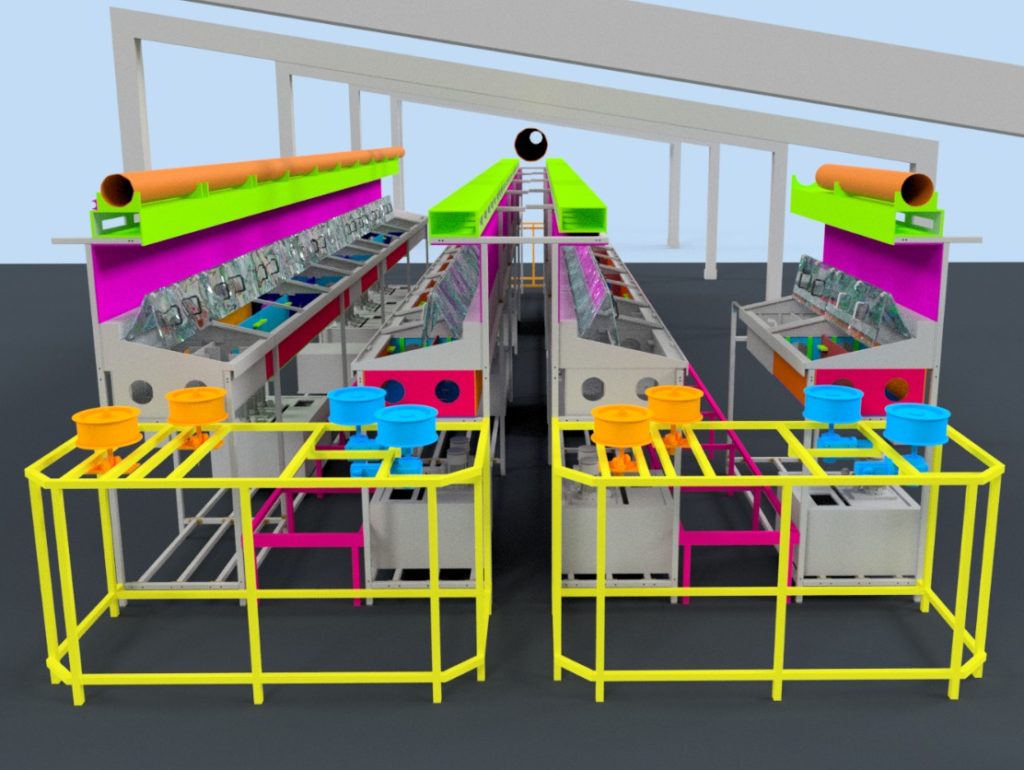

Barrel Plating Machine

When designing a drum automation, the functions of the units play a particularly important role.

It is therefore important to include economic, ecological and quality manufacturing factors. These include saving on operating resources, uniform and optimal layer thickness distribution, reduction of carryover losses, selection of material, manufacturing process and drum contacting.

Our systems are freely programmable and have separate work and storage containers.

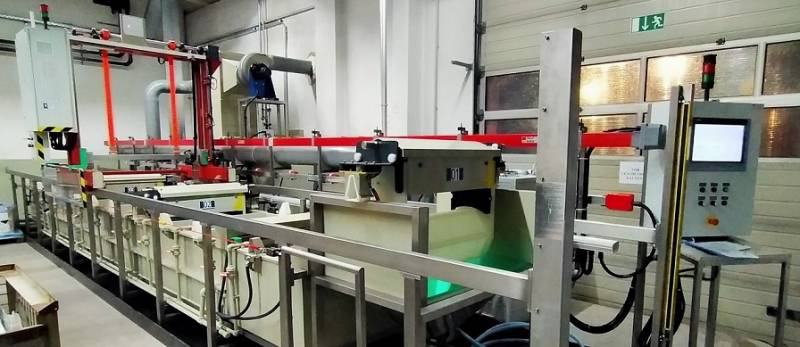

Ventilation systems

Exhaust and supply air systems

In the chemical industry, production facilities need efficient and constantly operated ventilation systems. Apart from the legal obligation, the investment pays off in a very short time thanks to the recovery of waste heat. This reduces your heating and energy costs. We integrate the heat recovery of the systems as well as other unused heat energy sources into the company. A sophisticated ventilation system creates a sustainable energy cycle.

System for exhaust gas purification or gas scrubber

In order to protect the environment, these exhaust gases and vapors must be separated from the exhaust air before the process air is ejected into the atmosphere. The main areas of application include the chemical and pharmaceutical industries, printing and coating as well as automotive and industrial painting systems.

Ventilation for the process air

Ventilation for process air are an indispensable part of exhaust air purification systems in industry. This serves to ensure a uniform air flow and an extraordinary cleaning of pollutants in the subsequent processes. With the low energy consumption you can reduce your additional costs. Quieter fans for a more pleasant working environment. Robust and corrosion-resistant constructions for long-lasting use of our process air fans.

Our focus is on individual and needs-oriented construction that meets your specific requirements! In this way, we guarantee optimized functionality and ensure that the exhaust air system is not undersized and therefore dissatisfied before commissioning. The fans always have a small surplus of power so that they can be used when larger requirements or changes occur and you can use your systems over the long term.