Reel-to-Reel electroplating line according to your needs

Standards are defined by OTMK“new construction in every project”. At OTMK, standards are the wheel for continuous improvement that is time-tuned.

Our team of engineers will support you in creating reel-to-reel electroplating line that are individually tailored to your needs.

We speak the same language as our partners in the areas of quality (ISO9001, IAF16949, CQI), mechanical engineering, process chain, chemistry and automation.

In continuous systems for cleaning, polishing and finishing strips and stamped products, we design the strip electroplating systems according to product requirements.

The properties of the material and the spatial conditions are determined in order to design an optimal solution for your concerns. Our systems can be designed for small and large rooms.

We are familiar with all types of reel-to-reel electroplating lines, as well as unwinding and rewinding, straightening, feeding, oiling, after-treatment and part connection.

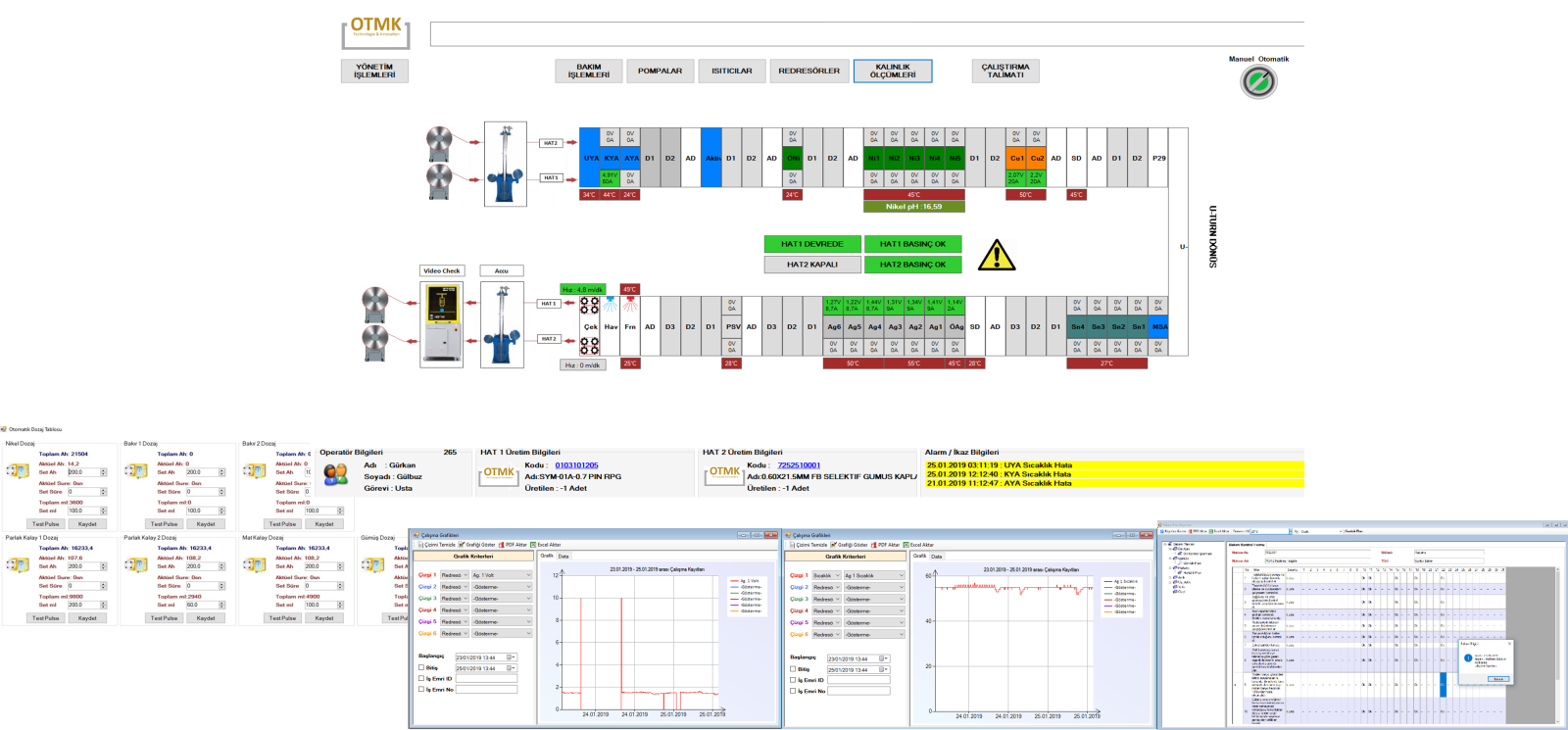

Our vision is to produce user-friendly, comfortable automatic systems. Complex process chains and with high data acquisition, we visualize the strip electroplating system according to industry standards.

An additional major strength of OTMK is bringing existing reel-to-reel electroplating line up to date, “retrofitting” we call it. First and foremost, it is very important for us to use the existing resources. Then a new reel-to-reel electroplating linem comes into question.

When investing in a new or existing reel-to-reel electroplating line, it is very important to conduct an as-is analysis. The actual analysis of OTMK is very extensive and consists of practical and theoretical parts.

Make use of the OTMK IS analysis and contact us without hesitation

info@otmk-group.com